| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

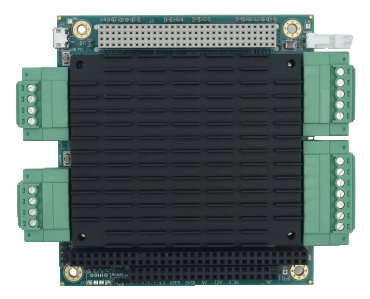

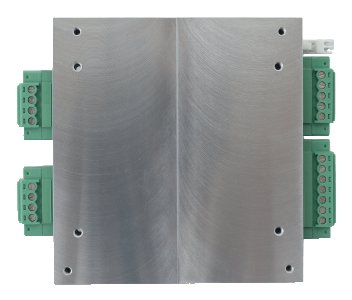

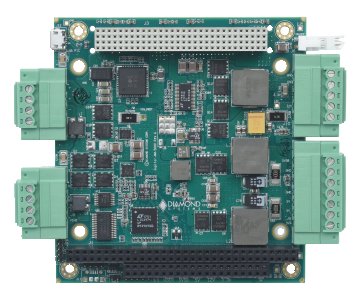

Jupiter-MM-5000 high-efficiency, high-precision 218W power supplies consist of a PC/104 form factor module with complete DC-DC voltage regulator circuitry, integrated thermal solution, detachable screw terminal block I/O connections, and PC/104 bus connectors. The wide input voltage range of 7 to 34VDC is compatible with industry standard 12V, 24V, and 28V inputs. On-board intelligence provides an unsurpassed level of control, monitoring and safety. All features are accessible and configurable via benchtop application software plus a programming library for real-time control. The Jupiter-MM-5000 uses a state-of-the-art design with the latest generation high efficiency components. It delivers efficiency as high as 95 percent, reducing input power requirements as well as heat generation. Jupiter-MM-5000 was engineered for rugged applications such as automotive or on-vehicle. Extended temperature operation of -40°C to +85°C is tested and guaranteed. Low-profile, surface mount components reduce susceptibility to shock and vibration. Both a low profile heat sink and heat spreader cooling options are available. I/O connections are made with locking screw terminal blocks for the highest degree of ruggedness.

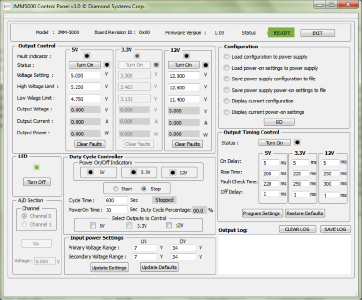

The full featured Jupiter-MM-5312 models include a system controller that offers advanced configuration, control, and monitoring features. The system controller is accessed via a USB port and is accompanied by benchtop configuration software as well as an application library for in-application real-time control.

The intelligent models of JMM-5000 include a system controller that offers advanced configuration, control, and monitoring features. The system controller is accessed via a USB port and is accompanied by benchtop configuration software as well as an application library for in-application real-time control. Below is a list of key features included. More details can be found in the Software user manual and Control panel user manual. Uninterruptible power supply (UPS): The power supply works with dual inputs (primary and backup, usually a battery) to enable uninterrupted operation. In case the primary input drops below a programmable threshold, the supply will automatically switch to the backup power source. Once the primary input returns to a suitable voltage, the supply automatically switches back to it. Power cycle control: (Programable duty cycle) The power supply can be programmed to turn on at programmable intervals for a programmable duration. This is useful for battery powered applications where the system does not need to be running continuously, and maximum battery lifetime is desired. Output voltage adjustment: Each output's voltage can be set to millivolt level accuracy under software control. This feature is useful for high power applications where voltage drop in the supply leads may be a concern. The power supply can be configured for a slightly higher output voltage to compensate for the anticipated drop in the output leads. Output voltage sequencing and slew rate control: The sequence for turn-on and turn-off, as well as the slew rate for each event, can be controlled in software. These parameters are stored in nonvolatile memory for automatic recall each time the unit powers up. Individual supply on/off control: Each output voltage (+12V, +5V, +5V standby, +3.3V, and +3.3V standby) can be independently turned on and off under software control. Individual supply monitoring: The output voltage and output current of each supply output can be monitored in real time. Input voltage monitoring: The voltage of both primary and secondary inputs is continuously monitored for reporting purposes and also to manage the UPS feature. Fault handling: The power supply monitors various conditions and can take action to prevent damage to the powered equipment or undesirable behavior. An interrupt can be generated to inform the system software to take desired action. Examples include shutdown in case of output overload or in case of primary input failure. Hiccup mode: In case of a fault condition, the power supply can be programmed to attempt auto-restart at repeated intervals to enable automatic recovery when fault conditions are removed. Data logging: The min/max input and output voltages, as well as ambient temperature, can be logged to on-board flash and made available to the system software in real time.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

www.diamondsystems.com | Sunnyvale, California USA | +1-650-810-2500 | sales@diamondsystems.com |